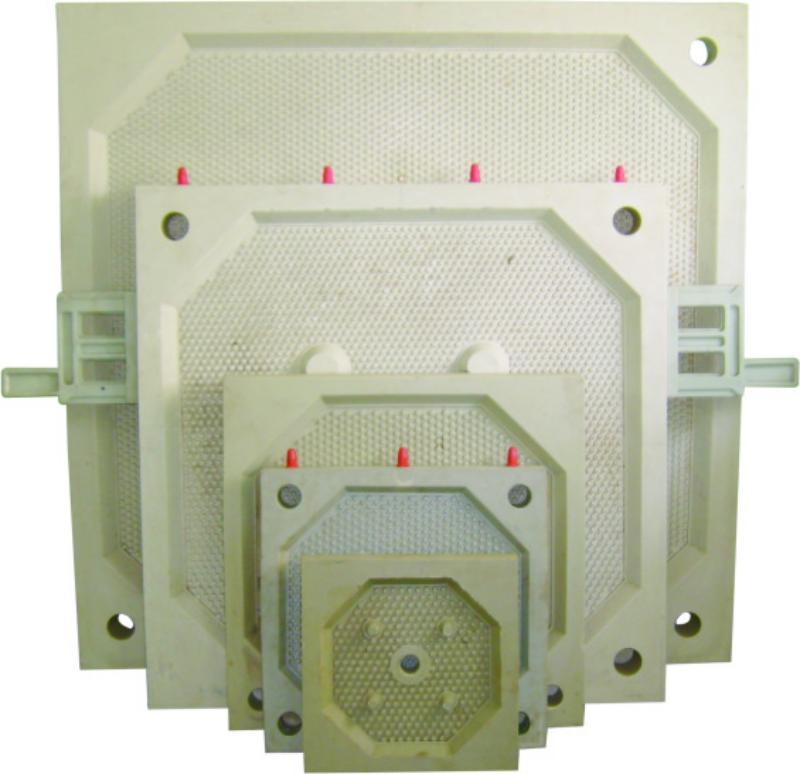

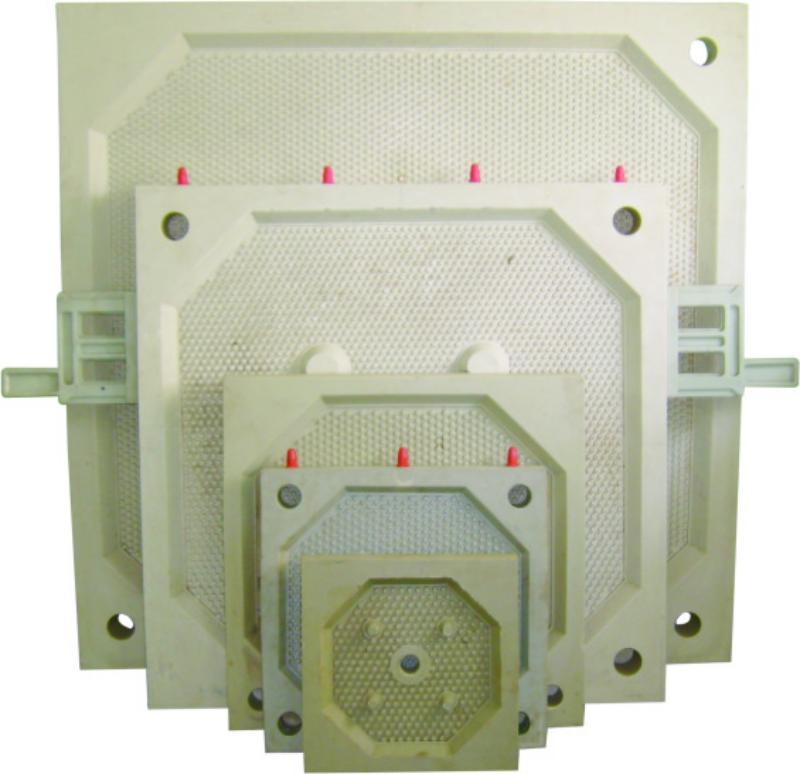

Filter Plates

Recessed Chamber Filter Plates

The recessed chamber filter plate made from polypropylene is a development of the plate and frame filter plate and has the same functionality.

The chamber plate frame is however integrated within the chamber filter plate thus significantly enhancing the plate's stability. This enables chamber filter plates to be used at much higher filtration pressure levels. Optional cake and plate thickness are available depending on the specific filtration conditions and application. The chamber filter plates are made of plastic and feature excellent chemical resistance and simple handling.

Size (mm): 250 mm to 2000 mm

Advantages of Chamber Filter Plates

- Single element and therefore cheaper than separate plates and frames

- Filtration pressures of up to 50 bar

- Suitable for high filtration temperatures

- Robust design with reinforced edges

- The recessed filter has a special pipped surface to protect the filter cloth and ensure excellent filtration

We provide different type of Recessed Chamber Filter Plates,

- Wash – NON Wash Option

- Standard Chamber Plate

- Standard Chamber Plate without Stay Boss

CGR Chamber Filter Plates

CGR has become common lingo in the filter press world. The term “CGR” refers to a caulked, gasketed, and recessed filter plate. CGR filter plate made of polypropylene has a special piped surface to protect the filter cloth, provide excellent filter cloth support and ensure excellent filtration.

CGR filter cloth is installed in grooves within the plate. Groove widths are typically between 1/4” and 3/8” wide. Groves containing an O-Ring around the sealing edge and filtrate holes form a tight seal when the plate pack is closed.

Size (mm): 470 mm to 2000 mm

Advantages of CGR Chamber Filter Plates

- Excellent sealing to allow for a virtually leak-free operation

- Made of polypropylene which offers excellent chemical/corrosion resistance, resistance to high temperatures,

- and ability to handle high pressure and flow

- Has a special pipped surface to protect the filter cloth and ensure excellent filtration

- Long life

Plate Frame Filter Plates

The oldest and longest known method for separating solids from liquids is the filter plate and frame system. Filter plates and frames were formerly made of wood but are now made of plastic like all other filter plate systems. Plastic offers excellent chemical resistance and meets the very high hygiene requirements. Plate and frame systems are typically used today in the pharmaceutical (pharmaceutical products and blood plasma) and food industries. The symmetrical cake chambers in plate and frame systems deliver excellent cake washing performance. Other benefits are the ability to use inexpensive filter cloths and disposable filters such as paper filters. The filter frame is interchangeable enabling the simple and inexpensive production of different cake thicknesses.

Size (mm): 610 mm to 1200 mm

Advantages of filter plate and frame systems

- Good wash results

- Cake thickenesses of up to 60mm

- Easily exchangeable cloths

- Use of disposable filters, e.g. paper filters

- Use of depth filter sheets

Membrane Filter Plates

Membrane plates are constructed in the same basic method as the recessed chamber plates. The drainage surface of the plates, however, are flexible. After filtration, when the chamber are filled with solids and while the filter press is stilled, air pressure is exerted behind the flexible drainage of the plate. The membrane in turn inflates or flexes outward and exert pressure on the filter cake which have been formed. The cakes are then squeezed to reduce the amount of remaining moisture prior to cake discharge.

Size (mm): 800 mm, 1000mm, 12000 mm, 1500 mm

Feature And Benefit Of Membrane Plate V/S. Chamber Plate

- Shorter cycle time

- Increased dry solids

- Reduced filtration time

- Easily replaceable

- Membrane are common and cab be used on either side of the plate

- Pip style drainage surface design for uniform flex.

- Reduced cake washing time

- Lesser wash water consumption

- Increased capacity

- Lower waste disposal cost

- Lower operating cost

- Excellent cake discharge

- Higher quality and valued end product

We provide bellow Membrane Filter Plates,

- Membrane Center Feed Plate

- Membrane Companion Plate

Our Special Filter Plates

- Adopter Filter Plates

- Thicker Plates

- Round filter plate (Size (mm): 800 mm)

Have a look

-

10" x 10" Filter Plate

10" x 10" Filter Plate

-

18" x 18" Filter Plate

18" x 18" Filter Plate

-

24" x 24" Filter Plate

24" x 24" Filter Plate

-

2000x2000 mm Filter Plate

2000x2000 mm Filter Plate

-

CGR filter plate

CGR filter plate

-

Companion Filter plate

Companion Filter plate

-

Recessed Plate

Recessed Plate

-

Round Filter Plate

Round Filter Plate